Description

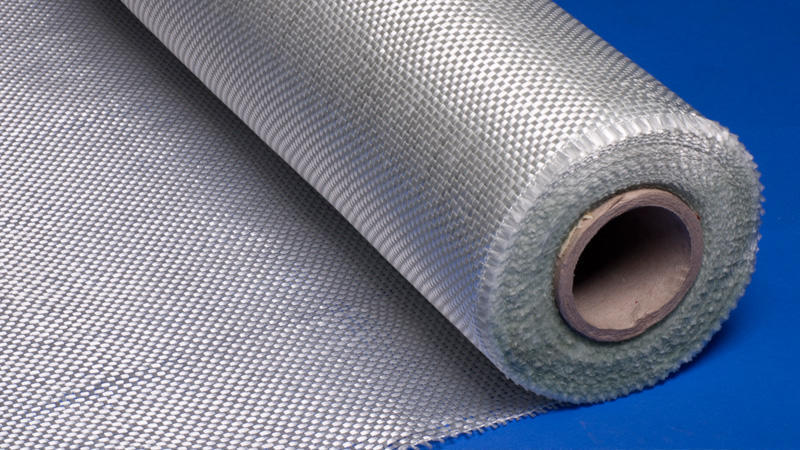

Woven Roving

WR glass combines the excellent mechanical and electrical properties of traditional E-Glass with the acid corrosion resistance of E-CR Glass. WR glass satisfies the requirements and description of both E-Glass and E-CR Glass according to ISO 2078 and ASTM D578.

Product Description

WR is composed of direct rovings woven into a fabric or tape. The input rovings are designed to give controlled wet-out and excellent laminate properties. The construction gives bi-directional (0°/90°) reinforcement and the strength of continuous filaments. Woven Roving Fabrics are designed to be compatible with multiple resin systems, and can be customized to meet specific product requirements. Available in 360,400,600 & 610 GSM

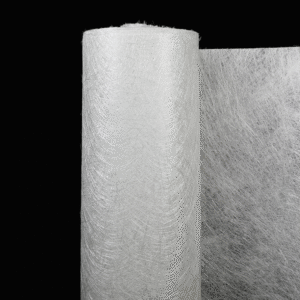

Product Application

Woven Roving Fabrics provide high-quality, global products designed to meet your performance and cost requirements. Woven Roving Fabrics provide the most economical solution for raising glass content of laminates and increasing laminate stiffness and impact resistance without adding thickness, weight, or other nonreinforcing materials. The fabric delivers cost effective solutions to your competitive reinforcement challenges, particularly large parts such as boat hulls and high-durability laminates such as underground storage vessels.

Product Reference

- Example : WR 610 1000

- WR : Woven roving

- 610 : Mass per unit area (g/m2)

- 1000 : Roll width (mm)

Technical Characteristics

| STH. WIDTH (MTS) |

LOSS ON IGNITION (%) |

MOISTURE (%) |

| 1.00 |

0.4 – 0.8 |

0.5 MAX. |

Products Available

| STANDARD REFERENCES |

AVG. MASS PER UNIT AREA (G/M2) |

| WR |

360 |

| 610 |

| 800 |

Laminate Characteristics

| PROPERTY |

VALUE |

TEST METHOD |

| Glass content (%) |

50 |

BS 2782 |

| Tensile Strength (Mpa) |

90-120 |

BS 2782 |

| Tensile Modulus (Gpa) |

6-7 |

BS 2782 |

| Flexural Strength (Mpa) |

190-210 |

BS 2782 |

| Flexural Modulus (Gpa) |

6-7 |

BS 2782 |

| Barcol hardness |

40 |

– |

Packaging

WR is wrapped in a polyethylene bag and packed in a cardboard box.

Storage Conditions

Woven Rovings should be kept in their original packaging and stored in a sheltered area.

The optimal conditions are :

- Temperature between 10 and 45°C inclusive,

- Relative humidity level between 35% and 85 % inclusive.

Note : If the storage temperature is less than 15°C, it would be advisable to put the pallets in the processing area for 24 hours before use. This is to avoid condensation. It is recommended that products be consumed using a first in, first out method within 12 months of delivery.