Description

PRODUCT APPLICATION

This is a multi-end E-glass roving with low sub-tex, designed for the manufacture of Sheet Molding Compound (SMC). This sizing is of medium solubility (60%) and contains a Silane coupling agent. Due to its outstanding characteristics, this roving is particularly recommended for applications where a very good surface aspect is requested.

FEATURES AND PRODUCT BENEFITS

- Excellent processability – Easy unwinding and chopping

- Good strand distribution

- No fuzz

- No static electricity

- Easy wet-out and impregnation

- Very good properties of molded parts – Good surface aspect

- No coloration

- Highly pigmentable

- Good mechanical properties

TECHNICAL CHARACTERISTICS (nominal values)

| Linear weight of roving (TEX) (g/km) |

Loss on Ignition (%) |

Moisture (%) |

| ISO 1889 |

ISO 1887 |

ISO 3344 |

| 2400 |

1.25 |

< 0.15 |

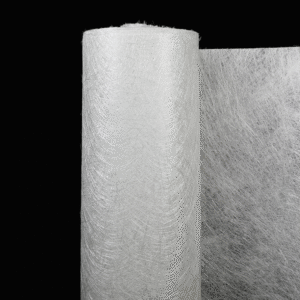

Multi-End Roving for SMC

PRODUCT DESCRIPTION

This is a multi-end roving, manufactured from a collection of continuous glass strands which are gathered, without mechanical twist, into a single bundle. The roving is then wound and shipped as a tubeless package ready for use at customer operations. This roving is manufactured with state-of-the-art equipment, innovative chemistry, and with a major commitment to statistical process control. OCV Reinforcements uses a Quality Management System certified to meet ISO 9002 standards.

PRODUCT AVAILABILITY (standard reference)

| Identification Number |

Bare glass linear density (tex) |

Approx. pkg weight (kg) |

Available Package |

| EC 2400 |

2400 |

19.0 |

Bulk Pack, Creel-Pak |

| Note: |

E |

: Type of glass |

|

C |

: Type of process, continuous |

|

|

: OCV Reinforcements code for sizing system |

PACKAGING AND PALLETIZATION (standard reference)

Pallet Dimensions

| Pallet Height, cm (in) |

95 (37) |

| Pallet Length, cm (in) |

114 (45) |

| Pallet Width, cm (in) |

114 (45) |

| Pallet Weight, net, kg (lb) |

912 (2011) |

| Number of layers |

3 |

| Package per pallet |

48 |

| Package Dimensions |

|

| Package Height, cm (in) |

26.5(10) |

| Package Diameter, cm (in) |

28(11) |

| Package Weight, kg (lb) |

19 (42) |

STORAGE

Unless otherwise specified, it is recommended to store glass fibre products in their original packaging in a cool, dry area. The best conditions are at a temperature between 15°C and 35°C and at a relative humidity between 35% and 85%. If these conditions are respected, glass fibre products should not undergo significant changes when stored for extended periods of time. If storage temperature is less than 15°C, it is recommended that rovings be transferred to the workshop at least 24 hours before intended processing, in order to prevent condensation. The packaging system is designed to allow stacking of two pallets. When stacking two high, care should be taken to correctly and smoothly place the top pallet. It is recommended to use a plywood plate between the two pallets in order not to damage the lower pallet.