Description

Sliplease 1602 is a solvent-based, semi-permanent mold release agent developed for FRP molding processes such as Hand Lay-up, Resin Transfer Molding and Vacuum Infusion. Sliplease 1602 is specifically developed for processes using unsaturated polyester and vinyl ester resins. It works well on both the types of molds: FRP and metal. It provides multiple releases per application. Sliplease 1602 is based on McLube’s proprietary ‘Hybrid Polymer Technology’ which combines unique application and performance features. These unique features along with the advantage they provide to the molders are:- Sealer and releaser combined in a single product Separate sealer not needed Less Inventory

- Reduced application time Time Savings

- No irritating odour/smell Applicator Friendly

- Forms durable film Multiple Releases per Application

- Glossy molded parts May Reduce Post-molding Operations such as Buffing

Typical Product Data

Color & Appearance Colorless & Clear Specific Gravity 0.69 – 0.73Method of Application

Please read Safety Data Sheet (SDS) before use.- Step 1 – Mold Cleaning:

- Use McLube’s Mold Cleaner 2B to clean the molds and remove any resin/pigment contamination, traces of previous release agent or wax.

- If the mold has been freshly buffed with a buffing compound, there is no need to clean the mold using Mold Cleaner 2B. It is recommended to directly proceed with application of release agent after buffing. Please note that in such a case, we recommend waiting for at least 4 hours between buffing and application of release agent step.

- Mold cleaning should be performed in a well ventilated area.

-

-

- Sliplease 1602 is moisture-sensitive. It is recommended to open the Sliplease 1602 container only when application is being performed. It should be sealed when not in use.

- Apply Sliplease 1602 on a clean and dry mold.

- Sliplease 1602 can be applied either by wiping or spraying.

Step 2 – Application of Sliplease 1602:

-

- Wiping:

-

- For wiping soft cotton cloths should be used. Two cloths are needed: one for application of Sliplease 1602 and another dry cloth for wipe-off.

- Saturate cotton cloth with Sliplease 1602. Gently wipe over mold surface. If the mold area is large, it is recommended to apply a section of approx. 2’ × 1’ in area at a time.

- After Sliplease 1602 has been wiped, use a dry cloth to wipe-off the release agent and to cover mold uniformly with release agent. Repeat above step for entire mold area.

- 3 coats (5-5-60 minutes): Apply a total of 3 coats of Sliplease 1602 on a freshly cleaned mold. These 3 coats should be applied with the interval of 5 minutes each. After the 3rd coat, wait for 60 minutes for release agent to form durable film on mold surface.

- Sliplease 1602 has been designed to complete the overall release agent application in a single session of 15-20 minutes.

- A curing time of 60 minutes after 3rd coat will ensure multiple releases.

- After few cycles when the release becomes difficult, apply 1 touch-up coat of Sliplease 1602 wait for 60 minutes continue molding.

-

Spraying:

- Sliplease 1602 can be sprayed using a compressed air/spray gun setup. The care must be taken to limit the exposure of Sliplease 1602 to atmosphere to only when needed.

- Transfer only adequate amount to spray gun. Apply 3 coats (5-5-60 minutes). Once the application is complete, transfer remaining Sliplease 1602 back to container and seal the container.

- The remaining steps are similar as mentioned in above section (Wiping).

-

Safety and Handling

The Safety Data Sheet (SDS) on Sliplease 1602, which accompanies initial shipment, should be reviewed prior to using the product. Freezing of the product should be avoided.Availability

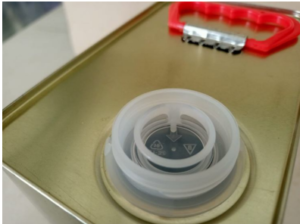

Sliplease 1602 is supplied in containers with moisture-proof seal. The information herein is believed to be reliable, but it the user’s responsibility to determine suitability of use; since we cannot know conditions of use, we make no warranties and assume no liability concerning use of the information. Nothing herein should be taken as an inducement to infringe any patent.Seal Opening Procedure – 1L and 5L containers of Sliplease 1602

|

|

|

|

Gently squeeze the cap and turn in anti-clockwise

direction to open red cap.

Gently squeeze the cap and turn in anti-clockwise

direction to open red cap.