Description

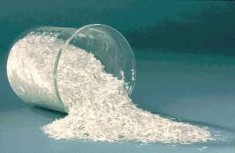

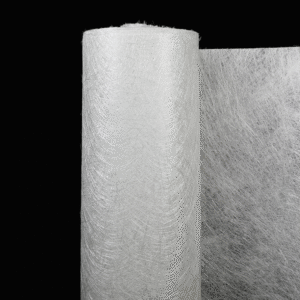

Chopped strand glass fiber combines the electrical and mechanical properties of traditional E glasses with the acid corrosion resistance of E-CR glass

Chopped strands are made from continuous strands of glass filaments designed to reinforce Phenolic grade resins. Chopped strands are specially designed to be compatible with phenolic resins based on silane coupling agent. Chopped strands have excellent dry flow coupled with good dispersion.

Chopped strands Is particularly suitable for producing BMC premix for friction applications and phenolic thermosets by compression or by injection moulding.

PRODUCT APPLICATION

Chopped strands are ideal for commercial mass production of friction facings, electrical & electronic equipment components etc.

IDENTIFICATION

Example: EC 6

E -Glass type

C -Continuous process

6 -Nominal length of chop (mm)

PRODUCTS AVAILABLE

Chopped strands are available in 3, 4.5, 6 and 12mm

PACKAGING

20-25 Kgs. in moisture proof polyethylene bags and packed in a cardboard carton or Kraft paper bag

.

TECHNICAL CHARACTERISTICS

| Characteristics |

Method of Measurement |

Individual Values |

| Minimum |

Nominal |

Maximum |

| Moisture Content (%) * |

ISO 3344: 1990 |

|

– |

0.20 |

| Size Content (%) * |

ISO 1887: 1995 |

0.90 |

1.15 |

1.40 |

STORAGE

Chopped strands should be stored in its original packaging in a dry and cool place. Best conditions are at temperature from 10 to 35°C and humidity between 35 and 85 %. If you store the product at lower temperatures, please move the soon to be processed pallets to the production area 24 hours ahead of time.